- Home

- Products

- Packaging Equipment

- Plastic Injection Molding Machine

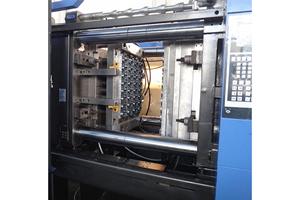

Plastic Injection Molding Machine

Plastic injection molding machine ranges from 68T-3000T, aiming at processing high quality plastic products efficiently. Therefore, it enjoys a wide popularity at home and abroad.

The introduction of advanced computer software helps to optimize the technical parameters of our products.

Automatic sampling system is used to test performance parameters of our new product.

Plastic injection molding machine has smaller deformation of the platen, smoother operation, longer working life, lower energy consumption, and easer operation, so it has won a high reputation in the market.

JND series plastic injection molding machine is a strong open platform, which can meet special requests from customers, like adding special features so as to suit all kinds of process techniques.

Our injection molding machine is designed to inject all kinds of plastic parts, PET bottle preform, engineering plastic, UPVC, PVC, PE pipe fitting, components for automotive, household appliance, electronics devices, telecommunication parts, etc.

Technical Parameters:| Model | JND1680 |

| INJECTION UNIT | |

| Screw Diameter (mm) | 50 |

| Screw L/D Ratio (L/D) | 25 |

| Shot Size (Theoretical) (cm3) | 491 |

| Injection Weight(PET) (g) | 520 |

| Injection Rate (g/s) | 175 |

| Plasticizing Capacity (g/446s) | 30 |

| Injection Pressure (Mpa) | 128 |

| Screw Speed (rpm) | 0-150 |

| CLAMPING UNIT | |

| Clamp Tonnage (kn) | 1680 |

| Toggle Stroke (mm) | 430 |

| Space Between Tie Bars (mm) | 460x460 |

| Max. Mold Heigh (mm) | 480 |

| Min. Mold Heigh (mm) | 180 |

| Ejector Stroke (mm) | 120 |

| Ejector Tonnage (kn) | 40 |

| Ejector Number(Piece) | 9 |

| Others | |

| Max. Pump Pressure (Mpa) | 16 |

| Pump Motor Power(KW) | 22 |

| Heater Power(KW) | 16.5 |

| Machine Dimension (L*W*H) (M) | 6.0*1.4*3.2 |

| Machine Weight (T) | 6.9 |

| Hoper Capacity (KG) | 50 |

| Oil Tank Capacity(L) | 320 |

| Model | JND2280 |

| INJECTION UNIT | |

| Screw Diameter (mm) | 60 |

| Screw L/D Ratio (L/D) | 25 |

| Shot Size (Theoretical) (cm3) | 780 |

| Injection Weight(PET) (g) | 826 |

| Injection Rate (g/s) | 273 |

| Plasticizing Capacity (g/446s) | 49 |

| Injection Pressure (Mpa) | 147 |

| Screw Speed (rpm) | 0-180 |

| CLAMPING UNIT | |

| Clamp Tonnage (kn) | 2280 |

| Toggle Stroke (mm) | 480 |

| Space Between Tie Bars (mm) | 510x510 |

| Max. Mold Heigh (mm) | 550 |

| Min. Mold Heigh (mm) | 200 |

| Ejector Stroke (mm) | 140 |

| Ejector Tonnage (kn) | 65 |

| Ejector Number(Piece) | 9 |

| Others | |

| Max. Pump Pressure (Mpa) | 16 |

| Pump Motor Power(KW) | 22 |

| Heater Power(KW) | 16.5 |

| Machine Dimension (L*W*H) (M) | 6.0*1.4*3.2 |

| Machine Weight (T) | 6.9 |

| Hoper Capacity (KG) | 50 |

| Oil Tank Capacity(L) | 320 |

| Model | JND2680 | |

| INJECTION UNIT | ||

| Screw Diameter (mm) | 70 | |

| Screw L/D Ratio (L/D) | 25 | |

| Shot Size (Theoretical) (cm3) | 1100 | |

| Injection Weight(PET) (g) | 1166 | |

| Injection Rate (g/s) | 380 | |

| Plasticizing Capacity (g/446s) | 60 | |

| Injection Pressure (Mpa) | 147 | |

| Screw Speed (rpm) | 0-190 | |

| CLAMPING UNIT | ||

| Clamp Tonnage (kn) | 2680 | |

| Toggle Stroke (mm) | 550 | |

| Space Between Tie Bars (mm) | 570x570 | |

| Max. Mold Heigh (mm) | 600 | |

| Min. Mold Heigh (mm) | 230 | |

| Ejector Stroke (mm) | 150 | |

| Ejector Tonnage (kn) | 65 | |

| Ejector Number(piece) | 9 | |

| Others | ||

| Max. Pump Pressure (Mpa) | 16 | |

| Pump Motor Power(KW) | 30 | |

| Heater Power(KW) | 21.5 | |

| Machine Dimension (L*W*H) (M) | 6.1*1.5*2.2 | |

| Machine Weight (T) | 8.0 | |

| Hoper Capacity (KG) | 50 | |

| Oil Tank Capacity(L) | 580 | |

| Model | JND3280 |

| INJECTION UNIT | |

| Screw Diameter (mm) | 75 |

| Screw L/D Ratio (L/D) | 25 |

| Shot Size (Theoretical) (cm3) | 1502 |

| Injection Weight(PET) (g) | 1590 |

| Injection Rate (g/s) | 350 |

| Plasticizing Capacity (g/446s) | 71 |

| Injection Pressure (Mpa) | 146 |

| Screw Speed (rpm) | 0-160 |

| CLAMPING UNIT | |

| Clamp Tonnage (kn) | 3280 |

| Toggle Stroke (mm) | 670 |

| Space Between Tie Bars (mm) | 660x660 |

| Max. Mold Heigh (mm) | 680 |

| Min. Mold Heigh (mm) | 240 |

| Ejector Stroke (mm) | 160 |

| Ejector Tonnage (kn) | 65 |

| Ejector Number(piece) | 13 |

| Others | |

| Max. Pump Pressure (Mpa) | 16 |

| Pump Motor Power(KW) | 37 |

| Heater Power(KW) | 23.8 |

| Machine Dimension (L*W*H) (M) | 6.9*1.7*2.5 |

| Machine Weight (T) | 12.0 |

| Hoper Capacity (KG) | 50 |

| Oil Tank Capacity(L) | 730 |

| Model | JND3980 |

| INJECTION UNIT | |

| Screw Diameter (mm) | 80 |

| Screw L/D Ratio (L/D) | 25 |

| Shot Size (Theoretical) (cm3) | 1689 |

| Injection Weight(PET) (g) | 1788 |

| Injection Rate (g/s) | 446 |

| Plasticizing Capacity (g/446s) | 70 |

| Injection Pressure (Mpa) | 152 |

| Screw Speed (rpm) | 0-165 |

| CLAMPING UNIT | |

| Clamp Tonnage (kn) | 3980 |

| Toggle Stroke (mm) | 700 |

| Space Between Tie Bars (mm) | 720x720 |

| Max. Mold Heigh (mm) | 800 |

| Min. Mold Heigh (mm) | 280 |

| Ejector Stroke (mm) | 160 |

| Ejector Tonnage (kn) | 110 |

| Ejector Number(piece) | 13 |

| Others | |

| Max. Pump Pressure (Mpa) | 16 |

| Pump Motor Power(KW) | 37 |

| Heater Power(KW) | 24.8 |

| Machine Dimension (L*W*H) (M) | 7.1*19*2.5 |

| Machine Weight (T) | 15.7 |

| Hoper Capacity (KG) | 50 |

| Oil Tank Capacity(L) | 750 |